Our editors curate highly rated brands that are first assessed by our rigorous ratings system. Buying through our links may earn us a commission—supporting the work we do. Learn more.

Nylon is the second most used synthetic fibre and is in so many everyday items, from toothbrushes to dresses, running gear, rope, and sneakers. But what is it, and where does it come from? And does it have an impact on the planet or its inhabitants? We ask: how sustainable is nylon?

A brief history of nylon

Apart from underwear and hosiery, nylon is also widely used in toothbrush bristles, umbrellas, knitwear, swimwear, and activewear. In fact, most of us interact with it on a daily basis, so it’s important to understand how the fabric is made, and its impact.

Nylon was the first fabric made entirely in a laboratory, and its invention represents the dawn of the age of synthetics. Nylon became widely available to the general public around the time of World War II, and it played two main roles in wartime. Firstly—thanks to its strength and durability—nylon was used extensively for military products, including parachutes, tents, ropes, and tyres. Secondly, nylon replaced everything that was once made from silk—such as silk stockings—as silk imports from Asia lessened and prices fluctuated.

Since then, nylon’s versatility and strength made it a favourite in the fashion industry, and we can’t understate its widespread usage. You’ll find it as a lightweight ripstop material for outerwear, as a stretchy, quick-drying material for bikinis, as a silky satin in dresses, a hard plastic in zipper teeth, mesh for caps and running trainers, and so much more. Today, 7 million tonnes of it is produced annually, according to Textile Exchange’s 2025 Materials Market Report.

What is nylon?

Essentially, nylon is a type of plastic derived from crude oil.

More specifically, nylons are a family of materials called polyamides (a name you might’ve encountered on garment labels), made from reacting carbon-based chemicals found in coal and petroleum in a high-pressure, heated environment. This chemical reaction, known as condensation polymerisation, forms a large polymer—in the form of a sheet of nylon. Nylon fibres are created using a melt spinning process, whereby the melted polymer is drawn through a spinneret—a device which looks similar to a shower head.

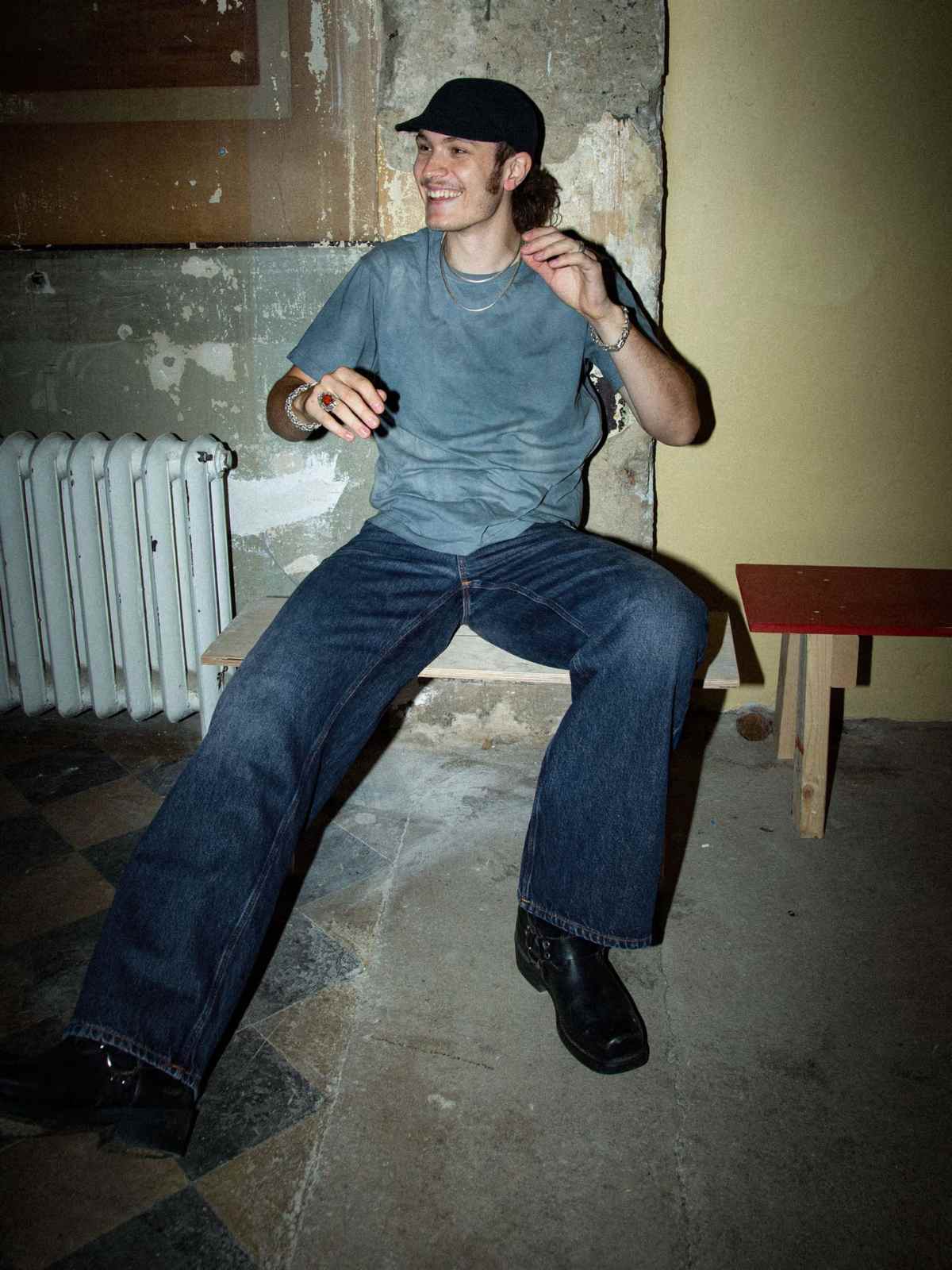

Nylon netting being produced in a factory.

Nylon’s impact on the planet

Different kinds of nylon have different properties, but the common threads between each are strength, durability, and ability to be moulded into shape. However, no form of nylon is biodegradable, so when stockings or old toothbrushes are thrown out, they go on to sit in landfill for hundreds of years. And when nylon is washed, it releases microplastics, or tiny bits of plastic, and they make their way to the ocean by the billions. In fact, they are one of the biggest sources of ocean and shoreline pollution, and they are killing marine life at a staggering rate. There are solutions out there to help manage microfibres, which we’ve detailed in our guide.

As nylon is in part derived from coal and petroleum, it is directly supporting some of the world’s dirtiest industries. The manufacturing process has several other direct environmental impacts:

- It produces nitrous oxide—a greenhouse gas that, it’s suggested, is 300 times worse than carbon dioxide.

- It’s a very thirsty process—large amounts of water are used for cooling the fibres, which can then be a source of environmental contamination and pollution.

- It’s also an energy-intensive process, which contributes to environmental degradation and global warming.

Are there more sustainable nylon alternatives?

Recycled nylon is an alternative to virgin nylon, though as Textile Exchange’s Materials Market Report (2023) noted, the market’s growth is slow owing to technical challenges, the quality and availability of feedstock (ie, the nylon to be recycled), and pricing issues.

Recycled nylon can be made using either mechanical or chemical recycling processes. There are also some bio-based alternatives to nylon that are derived from renewable materials, such as EVO by Fulgar, but it’s important to remember that even bio-based nylons are still a type of plastic. Ultimately, even recycled or bio-based nylons have challenges associated with biodegradability and microfibre shedding.

ECONYL, created by Aquafil, is an example of a nylon fibre made using a chemical recycling process. Nylon waste, such as discarded fishing nets, is depolymerised and then repolymerised to make a recycled nylon fibre of the same quality as virgin fibre. Loopamid is another example of recycled polyamide.

If you’re trying to determine the sustainability of a nylon garment, check whether it’s regenerated or recycled (and in particular, certified to the Global Recycled Standard). Given nylon’s inability to biodegrade, it’s also important to consider the lifecycle of a garment—washing the item infrequently and ensuring it has longevity in your wardrobe are key actions you can take, and ideally, the retailer you buy it from should offer a safe method of disposal, a reuse scheme, or guidance on what to do with the garment when you’re finished with it.

And if you’d prefer to consider a different material altogether, check out our lower-impact materials guide.